Introduction to DIY Electrical Engineering Projects

What is Electrical Engineering?

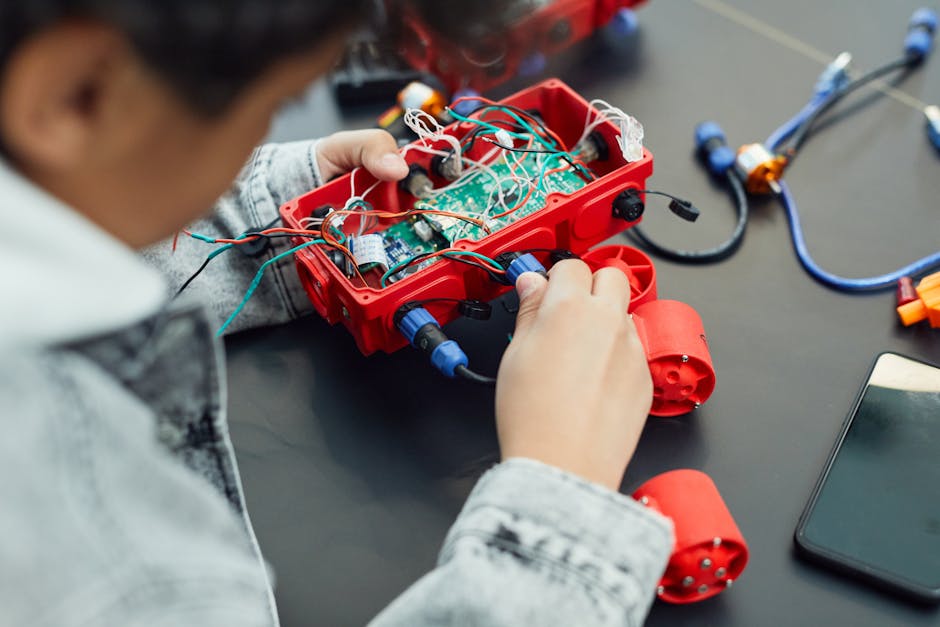

Electrical engineering is a fascinating field that deals with the study and application of electricity, electronics, and electromagnetism. It plays a pivotal role in designing, developing, and managing electrical systems and devices. From household appliances to massive power grids, electrical engineers impact our daily lives in countless ways. As someone who fondly recalls assembling simple electronic kits during childhood, the thrill of witnessing a circuit come to life is unmatched. It sparks creativity and problem-solving, essential skills for anyone interested in this domain.

Benefits of DIY Projects

Engaging in DIY Electrical Engineering projects offers numerous benefits that can enhance both personal and professional growth:

- Hands-on Learning: DIY projects provide practical experience, helping to solidify theoretical concepts.

- Problem Solving: Tackling challenges fosters critical thinking and innovation.

- Creative Expression: These projects allow individuals to express creativity while designing unique solutions.

- Cost-Effective: Building your own devices can save money compared to buying commercial products.

Not only do these projects deepen technical knowledge, but they also instill a sense of achievement when completing a design or fixing a circuit. Whether it’s crafting a simple LED circuit or developing a complex automation system, the journey of DIY electrical engineering is both rewarding and educational.

Essential Tools for Beginners

Multimeter Basics

A multimeter is an indispensable tool for anyone delving into electrical engineering; it measures voltage, current, and resistance. For beginners, understanding how to use a multimeter can significantly boost confidence. A memorable experience for many is the first time they used a multimeter to troubleshoot a faulty device — the “aha!” moment is truly exhilarating. Here are some basic functions you should familiarize yourself with:

- Voltage Measurement: Check the voltage across components.

- Current Measurement: Measure the flow of electricity.

- Resistance Measurement: Assess the resistance in a circuit.

Knowing how to switch settings and connect probes properly is essential for accurate readings.

Soldering Techniques

Soldering is another vital skill in electrical engineering, allowing components to be joined together securely. For beginners, mastering soldering can feel a bit intimidating, but practice makes perfect. Many enthusiasts fondly recall their first soldering project — a simple circuit board that gleamed with a sense of accomplishment.Here are some key techniques to keep in mind:

- Keep Equipment Clean: A clean soldering iron tip ensures better heat transfer.

- Use the Right Temperature: Too high can damage components; too low will not create a good joint.

- Practice on Scrap Boards: Experimenting helps build muscle memory without the fear of ruining a project.

With patience and practice, soldering becomes second nature, allowing builders to create reliable and long-lasting circuits.

LED Blinking Circuit Project

Materials Needed

Creating an LED blinking circuit is an exciting project that introduces beginners to basic electronic components. Here’s what you will need:

- LEDs (Light Emitting Diodes): Choose your favorite colors.

- Resistors: A common value is 220 ohms.

- Transistors: NPN transistors like the 2N3904 work well.

- Breadboard: For easy assembly without soldering.

- Jumper Wires: Multiple lengths to connect components.

- Power Source: A 9V battery or a power supply.

Reflecting on the past, assembling my first blinking LED circuit filled me with wonder as the light danced to life.

Step-by-Step Instructions

Building this circuit is a great way to learn about electronic components and circuit design. Follow these simple steps to get started:

- Set Up the Breadboard: Place the breadboard horizontally in front of you for easy access.

- Insert the LED: Connect the anode (longer leg) to a power rail and the cathode (shorter leg) to the ground rail.

- Connect the Resistor: Attach one terminal of a resistor to the cathode of the LED and the other terminal to the ground rail.

- Add the Transistor: Place an NPN transistor on the breadboard, ensuring the collector, base, and emitter are correctly connected:

- The collector connects to the cathode.

- The base connects to a pin of the microcontroller (if used) or a resistor leading to the power supply.

- The emitter connects to the ground.

- Power the Circuit: Connect the power source to the designated power rail on the breadboard.

- Test the Circuit: After all connections are made, power it on. If assembled correctly, the LED should blink!

Building this circuit not only demonstrates the principles of electricity but also lays the foundation for more complex projects. Enjoy the process and watch your knowledge and skills grow!

Simple DC Motor Control Project

Overview of DC Motors

DC motors are an integral part of many DIY projects. They convert electrical energy into mechanical energy, allowing devices to move and operate efficiently. Reflecting on early projects, the ability to control a rotating motor was always a highlight. Understanding the basics of DC motors can foster creativity and innovation. Key components include:

- Stator: The stationary part, typically containing coils or magnets.

- Rotor: The rotating part that interacts with the magnetic field.

- Commutator: Ensures the current flow reverses in the rotor, maintaining rotation.

With their simplicity, DC motors can be found in everything from toy cars to larger robotics projects, inspiring individuals to explore their functionalities further.

Wiring and Programming Guide

Controlling a DC motor requires both wiring and programming to operate effectively. Follow this guide to set up your project:

- Materials Needed:

- DC Motor

- Arduino Board (or another microcontroller)

- H-Bridge Motor Driver (like L298N)

- Jumper Wires

- Power Supply

- Breadboard (optional)

- Wiring the Circuit:

- Connect the DC motor to the output terminals of the H-Bridge.

- Connect the H-Bridge input pins to the digital pins on the Arduino.

- Connect the power supply to the H-Bridge for motor power and connect the ground together.

- Programming the Arduino:Here’s a simple code snippet to control the motor:

const int motorPin1 = 9; // Pin connected to IN1 on H-Bridgeconst int motorPin2 = 10; // Pin connected to IN2 on H-Bridgevoid setup() { pinMode(motorPin1, OUTPUT); pinMode(motorPin2, OUTPUT);}void loop() { digitalWrite(motorPin1, HIGH); // Motor rotates one way delay(2000); // Rotate for 2 seconds digitalWrite(motorPin1, LOW); // Stop the motor digitalWrite(motorPin2, HIGH); // Rotate the other way delay(2000); // Rotate for 2 seconds digitalWrite(motorPin2, LOW); // Stop the motor} - Test the Motor: Once the wires are connected and code uploaded, power on the circuit. The motor should rotate in one direction, stop briefly, and then rotate in the opposite direction.

Engaging in this simple DC motor control project not only enhances your understanding of motors but also lays the groundwork for more advanced applications, like robotic projects or automation systems. Enjoy the journey of discovery!

Arduino Traffic Light Project

Introduction to Arduino

Arduino is a popular open-source platform that makes programming simple, engaging, and accessible for beginners. With its user-friendly interface and a vast community, Arduino opens doors to countless creative electronic projects. Many enthusiasts recall their first experience with Arduino; for me, it was the excitement of building a functioning project from scratch. It's an ideal tool for learning essential concepts in electronics and programming.Key features of the Arduino platform include:

- Easy-to-Use IDE: The Integrated Development Environment (IDE) is straightforward, perfect for newcomers.

- Versatile Boards: Different models cater to various project sizes and complexities.

- Rich Libraries: Abundant libraries simplify hardware control, from LEDs to motors.

With Arduino, anyone can bring ideas to life, making it a perfect fit for our traffic light project.

Coding the Traffic Light Algorithm

Coding a traffic light simulation with Arduino is an excellent way to practice both programming and circuit design. Here’s how to get started:

- Materials Needed:

- Arduino Uno (or compatible board)

- 3 LEDs (Red, Yellow, Green)

- Resistors (220 ohms)

- Breadboard and jumper wires

- Wiring the Circuit:

- Connect each LED to the digital pins on the Arduino:

- Red LED to Pin 2

- Yellow LED to Pin 3

- Green LED to Pin 4

- Connect the other terminal of each LED to the ground through a resistor.

- Connect each LED to the digital pins on the Arduino:

- Writing the Code: Here’s a simple code example for the traffic light algorithm:

const int redPin = 2;const int yellowPin = 3;const int greenPin = 4;void setup() { pinMode(redPin, OUTPUT); pinMode(yellowPin, OUTPUT); pinMode(greenPin, OUTPUT);}void loop() { digitalWrite(redPin, HIGH); delay(5000); // Red for 5 seconds digitalWrite(redPin, LOW); digitalWrite(greenPin, HIGH); delay(5000); // Green for 5 seconds digitalWrite(greenPin, LOW); digitalWrite(yellowPin, HIGH); delay(2000); // Yellow for 2 seconds digitalWrite(yellowPin, LOW);} - Running the Code: Upload the code to the Arduino board. The LEDs will illuminate in the sequence of a standard traffic light, simulating the traffic signal process.

This Arduino traffic light project not only demonstrates basic coding principles but reinforces knowledge of circuits and component operation. It's a fun and practical way to see your code come to life! Enjoy your creativity and experimentation!

Basic Electronics Prototyping

Breadboarding Basics

Breadboarding is an essential skill for any electronics enthusiast, providing a platform to build and test circuits without soldering. This temporary setup allows for quick modifications, which is invaluable for learning and experimentation. I distinctly remember my first attempt using a breadboard; it was a mix of excitement and confusion! Understanding how to use a breadboard can enhance your prototyping experience.Here are the basic components of a breadboard:

- Power Rails: Often found along the top and bottom, these are used to distribute power throughout your circuit.

- Terminal Strips: The central area where components are inserted; each column on this strip is electrically connected.

- Jumpers: Wires that connect points on the breadboard.

When working with a breadboard, always double-check connections to ensure a successful circuit build!

Circuit Design Tips

Designing effective circuits requires both creativity and thoughtfulness. Here are some useful tips to help you craft successful designs:

- Plan Your Layout: Sketching your circuit on paper before assembling can prevent confusion while building. It helps organize components logically and anticipate any layout challenges.

- Use Color Coding: Using different colored wires for power (red), ground (black), and signal connections can simplify troubleshooting and help you track the flow of electricity.

- Start Simple: Begin with basic circuits and gradually introduce complexity. This approach builds confidence and solidifies foundational knowledge.

- Test As You Go: Regularly check your connections and component functionality during assembly. This methodology can save time on troubleshooting later.

- Document Your Work: Keeping a log of your designs and modifications helps track what works and what doesn’t, making it easier to replicate successful projects in the future.

By incorporating these core principles into your prototyping process, you’ll create more efficient and reliable electronic circuits. Embrace the learning journey and enjoy the satisfaction of bringing your ideas to life! Whether you’re building for fun or practical applications, effective prototyping can enhance your experience in electronics.

Voltage Regulator Circuit Project

Understanding Voltage Regulation

Voltage regulation is a crucial concept in electronics that ensures devices receive a consistent voltage level. Without proper regulation, fluctuations can damage components or cause erratic performance. In my early projects, I learned the importance of voltage regulation the hard way when an unregulated power supply fried a microcontroller. Now, understanding how to create a stable voltage output is essential.Here's a basic overview of voltage regulation types:

- Linear Regulators: Provide a stable output by dissipating excess voltage as heat, ideal for low-power applications.

- Switching Regulators: Use a high-frequency switch to efficiently convert voltages, suitable for high-current applications.

Grasping these principles provides the foundation for building reliable circuits!

Building the Regulator Circuit

Building a simple voltage regulator circuit can enhance your understanding of regulation while providing a useful power supply for other projects. Follow these steps to create your own:

- Materials Needed:

- Voltage regulator (e.g., LM7805 for a 5V output)

- Capacitors (typically 0.33µF and 0.1µF)

- Input and output power sources

- Breadboard and jumper wires

- Circuit Design:

- Connect the input pin of the LM7805 to your unregulated power source (e.g., 9V).

- Connect a 0.33µF capacitor across the input pin and ground.

- Attach another capacitor (0.1µF) across the output pin and ground.

- The output pin will provide a regulated 5V for your components!

Here’s a simplified schematic to guide your assembly:

+9V ----> Vin (LM7805) ----> Vout (5V) | | | | 0.33µF 0.1µF | | GND GND- Testing the Circuit: After assembling the circuit, power it on and use a multimeter to verify the output voltage at the Vout pin. You should see a steady 5V output, perfect for powering your projects!

By mastering the construction of a voltage regulator circuit, you lay the groundwork for future projects requiring stable power. Engage in this hands-on experience to deepen your understanding and enhance the reliability of your designs. Enjoy the sense of accomplishment that comes with building a functional power supply!

Power Supply Design for Beginners

Types of Power Supplies

Understanding the different types of power supplies is essential as you delve into electronics. Each type serves unique functions and applications, making it crucial to choose the right one for your project.During my first foray into power supply design, I found it enlightening to explore the various options available:

- Linear Power Supplies: These convert high voltage AC to a lower DC voltage through a simple and straightforward process. They're known for low noise but can be inefficient due to heat dissipation.

- Switching Power Supplies: More efficient than linear types, they use high-frequency signals to convert voltages. While they can be a bit more complex, they are ideal for high-power applications where efficiency is key.

- Battery-Powered Supplies: Perfect for portable projects, batteries can supply DC voltage. However, they require consideration for lifespan and recharging.

Each type is well-suited for specific scenarios, making knowledge of their differences essential for any project.

Design Considerations

When embarking on power supply design, several factors should guide your decisions to ensure a successful outcome:

- Voltage and Current Requirements: Determine the voltage and current demands of your circuit. This guides your choice of power supply.

- Efficiency: Consider the efficiency of the power supply to minimize heat generation and extend component life.

- Noise and Ripple: In sensitive circuits, regulating output noise is crucial. Using capacitors and filters can help reduce these issues.

- Size and Weight: For portable projects, compactness becomes a factor. Switching supplies are often smaller and lighter compared to linear options.

- Heat Management: Proper heat dissipation must be considered, especially for linear power supplies. Heatsinks and ventilation slots may be necessary.

- Cost: Budget constraints also influence your design choice. More complex power supplies may provide efficiency but can be more expensive.

Reflecting on my early designs, I learned that spending time understanding these considerations could drastically reduce troubleshooting time later on. It's all about setting the stage for a smooth build.By embracing the various types and considerations of power supply design, beginners can create reliable and efficient circuits for their projects. This knowledge not only fosters better designs but instills confidence in tackling more advanced projects. Enjoy your design journey and innovation in the world of electronics!

Electric Car Prototype Project

Overview of Electric Vehicles

Electric vehicles (EVs) have revolutionized the automotive industry, offering a sustainable alternative to traditional gasoline-powered cars. By converting electrical energy from batteries into movement, EVs contribute to reducing carbon emissions and reliance on fossil fuels.I fondly recall my first ride in an electric vehicle; the silent operation and instant torque were exhilarating! Understanding the components that make up these vehicles is key to grasping their advantages and challenges. Here's a brief overview of essential elements in EVs:

- Battery Pack: The powerhouse of the vehicle, typically lithium-ion, influences range and charging times.

- Electric Motor: Converts electrical energy into mechanical power.

- Regenerative Braking: A system that recovers energy during braking, enhancing efficiency.

- Charging Infrastructure: Includes home chargers and public charging stations, crucial for convenience and usability.

With increasing interest in environmental sustainability, building a small-scale electric car prototype can provide hands-on experience in this exciting field.

Building a Small-Scale Prototype

Creating a small-scale electric car prototype involves several key steps and components. Here’s how to get started:

- Materials Needed:

- Chassis: Use lightweight materials like plastic or aluminum.

- Electric Motor: A small DC motor (e.g., 12V) for propulsion.

- Battery: A rechargeable lithium-ion battery pack.

- Wheels: Choose lightweight, durable wheels for smooth motion.

- Motor Controller: To regulate motor speed and direction.

- Microcontroller: An Arduino or similar board for control logic.

- Assembling the Prototype:

- Build the Chassis: Construct a sturdy base to hold all components together.

- Install the Electric Motor: Attach the motor securely to the chassis, ensuring proper alignment with the wheel system.

- Connect the Battery and Controller: Wire the battery to the motor controller, then to the motor.

- Set Up the Microcontroller: Connect the motor controller to an Arduino, writing a simple code to control motor speed and direction based on input from sensors or buttons.

- Testing: Once assembled, test the prototype in a safe environment. Adjust the code and wiring as necessary until it runs smoothly.

Reflecting on my prototype experience, building a small-scale electric car provided invaluable insights into engineering principles and electric vehicle mechanics. Each challenge faced led to a greater understanding of the technology and its applications.Embarking on the electric car prototype project not only enhances technical skills but also fosters a deeper appreciation for sustainable transportation. Enjoy the innovative journey as you push the boundaries of your creativity and technical expertise!

pexels

Home Automation System Project

Introduction to Home Automation

Home automation refers to the use of technology to control and monitor various home systems through the internet or local networks. This can include lighting, heating, security, and appliances, enhancing convenience while improving energy efficiency.I vividly remember the first time I entered a smart home; controlling lights and temperature from my phone felt like stepping into the future! Today, home automation not only adds comfort but also allows homeowners to save on energy costs and enhance security.Key components of a home automation system typically include:

- Smart Devices: Lights, thermostats, cameras, and appliances integrated with automation capabilities.

- Control Hub: A central device (like a smart speaker) that connects and manages all your smart devices.

- Mobile Apps: Applications that allow remote control and monitoring from anywhere.

By incorporating these technologies, a home automation system can truly facilitate a seamless living experience.

Integrating Sensors and Actuators

To build a home automation system, integrating sensors and actuators is essential. Sensors detect changes in the environment, while actuators execute commands based on those changes. Here’s how to get started:

- Materials Needed:

- Sensors: Common options include motion sensors, temperature sensors, and door/window sensors.

- Actuators: Smart light bulbs, smart plugs, or relays to control various devices.

- Microcontroller: An Arduino or Raspberry Pi to serve as the control unit.

- Communication Modules: Wi-Fi or Zigbee modules for connectivity.

- Power Supply: Ensure all components have appropriate power sources.

- Designing the System:

- Planning: Decide which sensors and actuators you want to integrate based on your automation goals (e.g., automated lighting based on occupancy).

- Wiring: Connect sensors to the microcontroller inputs and actuators to the outputs.

- Programming: Write a code to process sensor inputs and trigger actuators accordingly. For example, the code can turn on lights when a motion sensor detects movement.

- Testing and Refining:

- After assembly, test the system in your home environment. Adjust sensor ranges and actuator responses as necessary to ensure optimal performance.

Remember, my initial home automation project taught me the importance of fine-tuning sensor sensitivity for accurate control. Taking time to adjust settings ensured a seamless user experience.By integrating sensors and actuators into a home automation system, you unlock countless possibilities for enhancing your daily life. As you explore this project, enjoy the creative processes and the satisfaction of making your home smarter and more efficient!